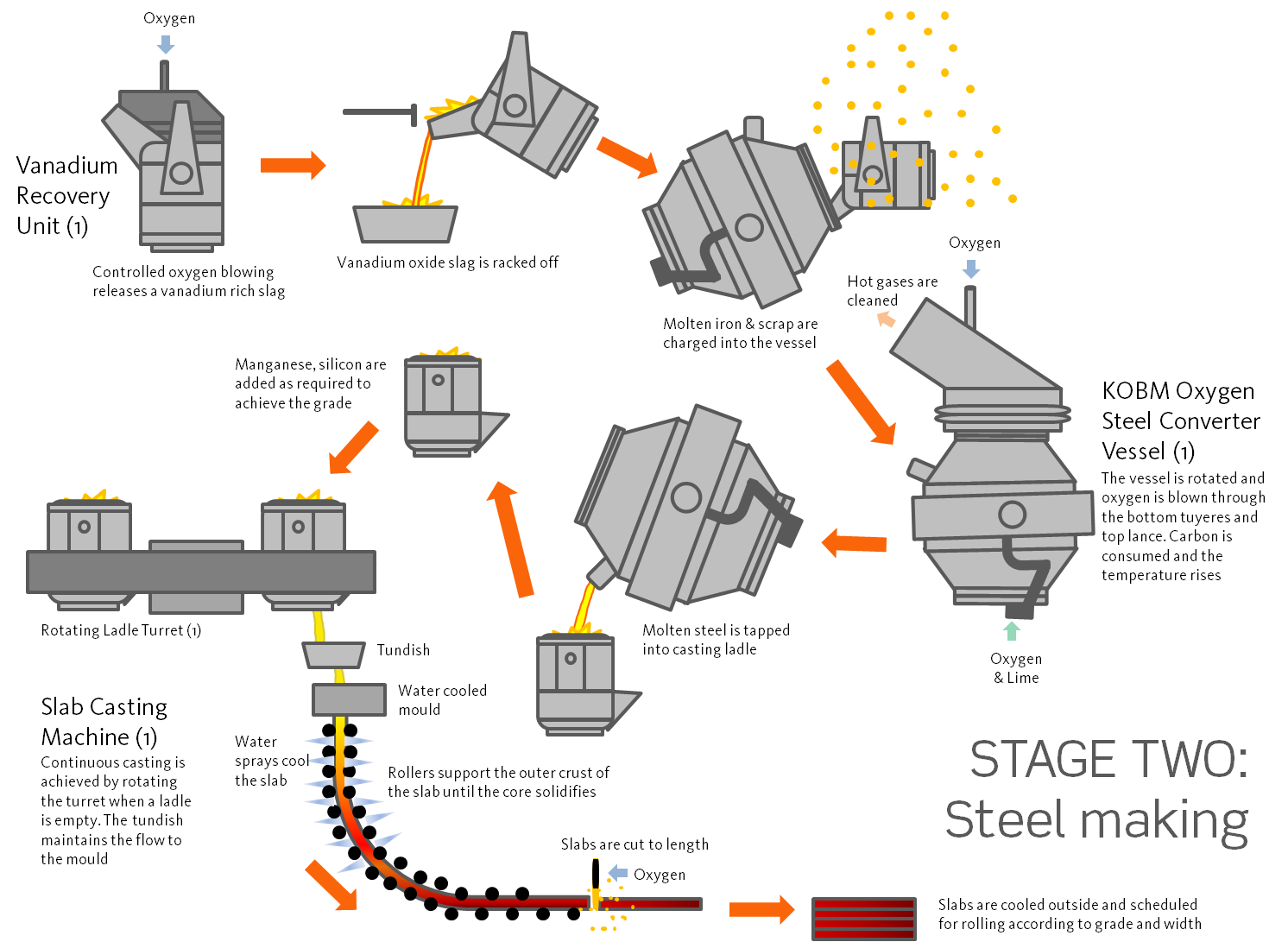

Discusses the application of the results of research conducted over the last ten years at universities, research centers, and industrial institutions. Hans-Jörg Krassnig, Head of Electric Steelmaking at Primetals Technologies, provides answers to these questions and shares his fascination with the raw power of the most efficient recycling machine created by manthe electric arc furnace. Co-treatment of Waste From Steelmaking Processes: Steel Slag-Based Carbon Capture and Storage by Mineralization.Examines the energy saving and emissions abatement efficiency for potential solutions to emission control and reduction in steelmaking plants Making steel Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature.Presents the most recent technological solutions in productivity analyses and dangerous emissions control and reduction in steelmaking plants.Due to negligible regulations and unparalleled growth in these industries during the past 15-20 years, knowledge of best practices and innovative technologies for greenhouse gas remediation is paramount, and something this book addresses. Later, by the complete de-carburization of pig iron, he succeeded in producing mild steels which were partly recarburized by the addition of ferromanganese. Secondary steelmaking involves adding or removing other elements such as alloying agents and dissolved gases. The advantages of steelmaking in the electric arc furnace are : All possible grades of steel can be melted Low capital outlay The melting process can be. The process consisted of the production of tool and high carbon steel by the partial de-carburization of Swedish pig iron (low sulphur and phosphorous). Primary steelmaking involves smelting iron into steel.

Ironmaking and steelmaking are some of the largest emitters of carbon dioxide (over 2Gt per year) and have some of the highest energy demand (25 EJ per year) among all industries to help mitigate this problem, the book examines how changes can be made in energy efficiency, including energy consumption optimization, online monitoring, and energy audits. Modern steelmaking processes can be divided into three steps: primary, secondary and tertiary. This book describes the available technologies that can be employed to reduce energy consumption and greenhouse emissions in the steel- and ironmaking industries. Modern steelmaking processes can be divided into three steps: primary, secondary, and tertiary as below: Primary Steelmaking: involves smelting iron ore into.

0 kommentar(er)

0 kommentar(er)